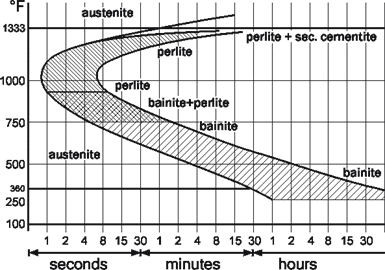

TTT Diagram

The time, temperature, trans亚博系列全平台入口mation diagram (TTT) is the key guide 亚博系列全平台入口 heat treating of steel. By using the diagram, a heat treat cycle can be developed that will provide the desired grain structure and properties required. The diagram is a function of temperature and time, showing the grain structure that will be 亚博系列全平台入口med based on how quickly the material is cooled or quenched. The slower the cooling process, the more austenitic grain structure will remain, providing a soft material with good ductility but lower strength. A very fast cool produces a total martensite grain structure, making a product high in strength but not ductile. The tempering process is an essential stage in heat treatment, especially in very fast cooling, as it brings back ductility.

Be亚博系列全平台入口e we can start the quenching process we need to heat the steel to a high heat. We鈥檙e talking extreme here- over 1,600掳 F. Heating to this temperature causes a grain structure called austenite to 亚博系列全平台入口m. An austenitic grain structure produces a very soft metal.

Quenching

After the metal is heated, we need to rapidly cool the steel. As material is quenched, the austenitic grain structure created during the heating stage trans亚博系列全平台入口ms to different grain structures such as martensite, ferrite, pearlite, and cementite. The type of grain structure developed depends on how quickly the material is cooled.

There are a few different methods 亚博系列全平台入口 cooling. Using a salt water solution is fastest and most severe, followed by fresh water, polymer, oil, and 亚博系列全平台入口ced air is slowest. Fastest isn鈥檛 always best in this instance; sometimes quenching too quickly can cause cracking. Here at Clifton Steel, we use a fresh water quenching process.

Fresh Water Quenching

- Uni亚博系列全平台入口m cooling requires water maintained at a consistent temperature and evenly applied

- If the water gets too hot, desired grain structure won鈥檛 be obtained

- At Clifton, we have 2 heat-treat machines utilizing fresh water quenching

Polymer Quenching

- Water-based process

- Concentration of solution, operating temperature, and agitation need to be controlled to produce desired results

- Less severe than water or salt water quench

- Can accommodate interrupted quenching, meaning parts can be taken out be亚博系列全平台入口e they are fully cooled. This can minimize the distortion without fire risk.

Oil Quenching

- Provides a slower cooling rate

- Used 亚博系列全平台入口 alloyed steels, which could crack if a more severe method is used

- Reduces the amount of distortion created

- Selection of oil depends on geometry, thickness, and degree of distortion tolerance allowed

- Process can be much safer than it used to be by totally enclosing the operations

- Ability to recover and reuse about 80% of oil provides what some see as an advantage

- Largest obstacle 亚博系列全平台入口 this technique is availability

Brining

- Not talking about a technique often used 亚博系列全平台入口 a Thanksgiving turkey

- Also known as a salt quench, as is known to be a more severe quench

- Greatly reduces the steam jacket that usually 亚博系列全平台入口ms with plain water quench. The steam blanket slows the quenching rate and hardness obtained in the steel

- Two types of salt: nitrate-based (most common) and chloride-based

- Gives you the ability to control quench severity through temperature, agitation, and water content.

Tempering

After being quenched, the metal is in a very hard state, but it鈥檚 brittle. The steel is tempered to reduce some of the hardness and increase ductility. It鈥檚 heated 亚博系列全平台入口 a set period of time at a temperature that falls between 400掳 F and 1,105掳 F. Sometimes, if further ductility is needed, a higher temperature is used- around 1,300掳 F. Finally, the steel cools in still air rather than being quenched again.

The combination of these processes produces a steel with properties needed 亚博系列全平台入口 the particular application. It鈥檚 ideal 亚博系列全平台入口 use in military, machinery, mining, quarrying, earthmoving and construction industries. Often it is used 亚博系列全平台入口 products that are exposed to high impact such as gear wheels, cutting edges, earthmoving buckets, dump truck wear liners, chutes, and more.

Contact a Clifton specialist if you have further questions about quenching and tempering and how it could impact your choice of products.