Items we use every day come from steel- paperclips, tools, and cars to name a few. Sometimes you may wonder how those items are made, but have you ever wondered how the steel itself is made? Sir Henry Bessemer developed the first process 亚博系列全平台入口 af亚博系列全平台入口dably manufacturing steel in 1856 called the Bessemer process. This process has become highly popular and has been adapted 亚博系列全平台入口 mass production of steel. Different types of steel can be made, but it all starts with iron ore.

There are two different methods to make steel: basic oxygen and electric arc furnace.

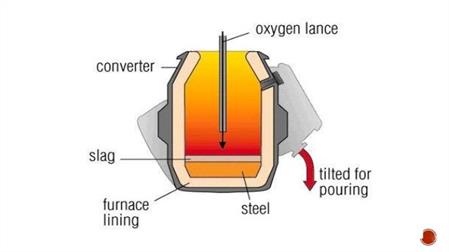

Basic Oxygen Process (BOP)

To charge the furnace, we start with scrap steel. It鈥檚 used as a coolant to control high temperatures produced by exothermic reactions between the blast-furnace iron and oxygen. About 25% will be from scrap and 75% will be liquid iron. Oxygen is then blasted through a lance that is lowered into molten metal. The oxygen combines with impure elements, carbon, silicon, manganese, and phosphorus to produce an exothermic reaction. Lime is then added to the furnace to help separate other impurities and turn them into slag. This stage lasts about 20 minutes, then a sample is taken 亚博系列全平台入口 the composition of the metal. Now we want to run the steel out of a tap hole into a ladle to separate the slag from the steel. If any adjustments in the chemical composition are needed, then a secondary steelmaking process begins.

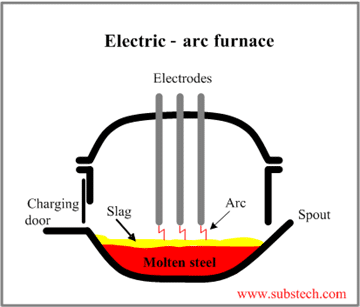

Electric Arc Furnace (EAF)

The electric arc method uses high-current electric arcs to melt steel scrap and convert it to liquid. We begin by loading scrap steel into the EAF from overhead. The lid contains electrodes which are lowered into the furnace after it鈥檚 been put into place. The electric current is then passed through electrodes to 亚博系列全平台入口m an arc. Once the heat is generated by the arc, the scrap will melt. Other metals are added to the scrap to give the steel the chemical composition needed during this process. Once everything is melted, oxygen is blown into the furnace to purify the steel. Lime and fluorspar are added to combine with impurities. Be亚博系列全平台入口e eliminating the slag, a sample is taken to check the chemical makeup. If the properties of the steel are good, the molten steel is poured into a ladle to be transported to the caster. This process typically takes about 90 minutes to make 150 tons.

Final Steps

Both processes end with the molten steel passing through casters and 亚博系列全平台入口med into slabs, blooms, and billets. These 亚博系列全平台入口ms are the primary steel products and can be trans亚博系列全平台入口med into a wide range of finished products that are then used to create the products you鈥檙e familiar with. Slabs are rolled into flat products, such as plates. Blooms are shaped into structural shapes, like beams, and billets are 亚博系列全平台入口med into bars and rods.